Buyer’s Guide: BelAire® Air Compressors

Compressor Requirements

Compressor Types

Compressor Groups

COMPRESSORS

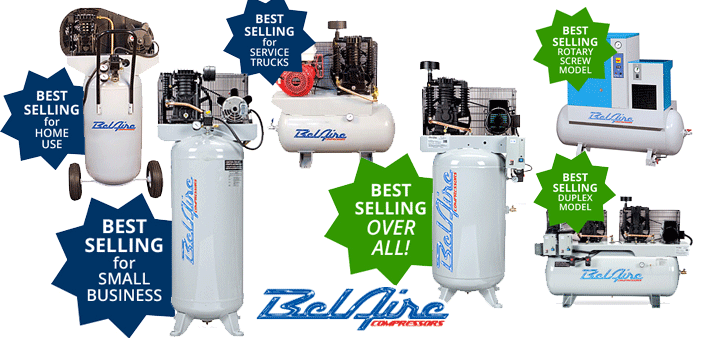

Best Sellers

MANUFACTURER INFO

Warranty & Customer Service

Duty Cycle

Duty cycle is the amount of continuous compressed air needed for the tools in use.

Most air tools are rated at a 35% duty cycle. For example, impact wrenches operate at around 35% duty cycle as they are running intermittently. However, anything that spins, chips, nibbles, grinds, polishes, etc. operates at closer to 100% duty cycle.

Total cfm

Total cfm is the total amount of air output needed.

For example, Body Shops typically estimate 12 – 15 cfm per user plus 25% for duty cycle. While, Mechanical Shops typically estimate 3 – 5 cfm per user plus 25% for duty cycle.

Power Supply

The electrical specifications for the installation location.

This includes the Voltage and Phase (single phase or three phase). The power requirements are very important for selecting the correct compressor model.

You may be able to locate your information at the supply box. The local electric company supplying the installation location can also provide the required information.

Work Style

Choices to make your investment last longer. Consider ease of use and comfort.

For example if your compressor needs to be in an enclosed work area, heat output and sound levels may be an issue to your work environment as well as the mechanical wear on your new compressor. Other considerations: Portability, Service Calls, Vertical vs. Horizontal Tanks.

Piston Compressor

The compression process is achieved through the motion of Pistons. The resulting friction creates heat. Therefore, Piston Compressors require resting/cooling periods and heat dissipation. The Duty Cycle is 70%.

Applications: Any use that is less than a 70% Duty Cycle. For example, tools that are run sporadically with frequent stops and starts. Examples would be impact wrenches, drivers and many tools found in mechanical shops.

Pros: Lower Cost

Cons: Inconsistent Air Output (70% Duty Cycle), Operational Heat, Noise

Rotary Screw Compressor

The compression process of Rotary Screws is a continuous sweeping motion. There is very little pulsation or surging of flow, as occurs with Piston compressors, resulting in a 100% Duty Cycle and a large volume of consistent air flow. There is also less heat due to less internal friction and less operational noise.

Applications: Any use requiring more than a 75% duty cycle. For example, tools that run almost continually without frequent stops and starts. Examples would be polishers, grinders and many tools found in body shops.

Pros: Consistent Air Output (100% Duty Cycle), Less Operational Heat, Quieter Operation

Cons: Cost

Piston Compression • Single Stage Models

FEATURES:

Start-Stop Pressure Switch Control

ASME Safety Valves Fully-Enclosed Belt Guard

Tank Drain and Discharge Valve

1 Year Warranty

SINGLE STAGE: Air is compressed one time resulting in typical maximum psi of 130 to 140.

• For small business, residence or any compressed air need

• Offers high volume

• Can operate on low amperage single phase power

• Mounted on rugged receiver tanks to improve the consistency of your air flow

PISTON COMPRESSION • SINGLE STAGE

Electric

• START-STOP PRESSURE SWITCH CONTROL

• ASME SAFETY VALVES FULLY-ENCLOSED BELT GUARD

• TANK DRAIN AND DISCHARGE VALVE

• 100% FACTORY TESTED AT FULL PRESSURE

• 1 YEAR “BUMPER TO BUMPER” WARRANTY

• PRODUCT LINEUP INCLUDES: 4 MODELS

Piston Compression • Two Stage Models

Start-Stop Pressure Switch Control

ASME Safety Valves Fully-Enclosed Belt Guard

Tank Drain and Discharge Valve

Magnetic Starters Included if Required

Full 2 Year Warranty (including valves)

ELITE MODEL FEATURES:

Magnetic Starter

Low Oil Switch and Automatic Tank Drain

5 – 7.5 HP “ELITE” include triple-pass Pump Mounted Aftercooler

Full 2 Year Warranty (including valves)

TWO STAGE: Air is compressed in the first, large cylinder (First Stage). Then, it is compressed further in the smaller cylinder (Second Stage). The Two Stage process results in higher pressure than Single Stage, typically 175 psi.

• Available from 5 to 10HP (Iron Series), delivering15.3 to 35 CFM at 100psi

• Comes complete with everything you need to optimize your work and minimize down time

PISTON COMPRESSION • TWO STAGE

Electric – Standard Models

• START-STOP PRESSURE SWITCH CONTROL

• ASME SAFETY VALVES FULLY-ENCLOSED BELT GUARD

• TANK DRAIN AND DISCHARGE VALVE

• MAGNETIC STARTERS INCLUDED IF REQUIRED

• 100% FACTORY TESTED AT FULL PRESSURE

• 2 YEAR “BUMPER TO BUMPER” WARRANTY

• PRODUCT LINEUP INCLUDES: 16 MODELS

PISTON COMPRESSION • TWO STAGE

Electric – Elite Models

• MAGNETIC STARTER IS MOUNTED AND WIRED

• LOW OIL LEVEL SWITCH PREVENTS THE MACHINE FROM RUNNING IN A LOW OIL CONDITION

• AUTOMATIC TANK DRAIN REMOVES CONDENSATION FROM THE TANK

• 5 – 7.5 HP “ELITE” INCLUDE TRIPLE-PASS PUMP MOUNTED AFTERCOOLER ELIMINATES UP TO 60% OF THE MOISTURE IN THE COMPRESSED AIR

• 100% FACTORY TESTED AT FULL PRESSURE

• 2 YEAR “BUMPER TO BUMPER” WARRANTY

• PRODUCT LINEUP INCLUDES: 12 MODELS

PISTON COMPRESSION • TWO STAGE

Electric – Quiet Performance (QP) Compressors

• LOW SOUND ENCLOSURE –

LESS THAN HALF THE NOISE GENERATED BY A STANDARD PISTON COMPRESSOR.

As low as 66 dba for a quieter workplace; Less than the 75-80 dba of a typical dishwasher or kitchen blender.

• THE VALUE OF A PISTON COMPRESSOR WITH THE NOISE LEVEL OF A ROTARY SCREW COMPRESSOR

• HIGH STRENGTH ABS MOTOR ENCLOSURE AND HEAT RESISTANT FOAM LINING OFFERS SUPERIOR SOUND REDUCTION; Cooler air is drawn into the bottom of the motor enclosure expelling the motor’s operational heat through the top vents.

• CAN BE INSTALLED ANYWHERE ELIMINATING THE NEED FOR AN ADDITIONAL ROOM

• LOW OIL LEVEL PROTECTION

• AUTOMATIC TANK DRAIN REMOVES CONDENSATION FROM THE TANK

• MAGNETIC STARTER

• CAST IRON CYLINDER

• HIGH TEMPERATURE SHUT DOWN; SUPERIOR COOLING – AUXILIARY FAN EVACUATES HEAT

• 80 GALLON VERTICAL ASME/CRN TANK

• 100% FACTORY TESTED AT FULL PRESSURE

• 2 YEAR “BUMPER TO BUMPER” WARRANTY

• PRODUCT LINEUP INCLUDES: 4 MODELS

PISTON COMPRESSION • TWO STAGE

Electric – Duplex Compressors

• TWO PUMPS, TWO MOTORS, ONE TANK –

MORE POWER FOR SINGLE PHASE ELECTRICAL CONDITIONS

The first pump starts. If it can not meet the air demand, the second pump comes on automatically doubling the air output. The next time, the second pump starts first so there is equal run time between the two pumps.

• ALTERNATOR

• MAGNETIC MOTOR STARTERS

• START-STOP DUAL PRESSURE SWITCH CONTROL

• 1″ TANK DISCHARGE VALVE

• FULLY ENCLOSED BELT GUARD

• ASME TANK AND SAFETY VALVES

• CAST IRON CYLINDER

• DUAL PRESSURE SWITCH CONTROL

• TRI-VOLTAGE MOTORS (3 PHASE)

• 100% FACTORY TESTED AT FULL PRESSURE

• 2 YEAR “BUMPER TO BUMPER” WARRANTY

• PRODUCT LINEUP INCLUDES: 19 MODELS

PISTON COMPRESSION • TWO STAGE

Gasoline – Service Truck Compressors

• 14 HP

• PUMP: 900 RPM; PUMP CRANKSHAFT SUPPORTED AT BOTH ENDS

• 12 VOLT ELECTRIC START AND RECOIL START

• BANDED BELTS; BELT GUARD CAGE DESIGN PROVIDES 35% MORE AIR CIRCULATION THAN A SOLID SHEET METAL GUARD

• AVAILABLE WITH HONDA, KOHLER, ROBIN AND BRIGGS ENGINES

• START KEY / PANEL; ELECTRIC AND RECOIL START

• START RELIEF VALVE FOR LOADLESS STARTS

• OIL MONITOR

• ENGINE SLOWDOWN (PILOT VALVE)

• FULLY ENCLOSED BELT GUARD

• UNIQUE EZ PULL TANK DRAIN – EASY CONDENSATION DRAINAGE FOR MACHINE UPKEEP

• ASME TANK AND SAFETY VALVES

• 3/4″ TANK DISCHARGE VALVE

• SHIPPED “WET” (READY TO USE) – NO START UP KIT REQUIRED

• 100% FACTORY TESTED AT FULL PRESSURE

• 2 YEAR “BUMPER TO BUMPER” WARRANTY

• PRODUCT LINEUP INCLUDES: 6 MODELS

Rotary Screw Compression • One Stage Models

Low Sound Enclosure

150 psig Standard (125 psig available 10-15 hp)

Continuous Operating Capability

Space Saving Design, <12 ft2

Across-The-Line Motor Starter

ASME/CRN Receiver Tank (5 – 7.5HP – 60 Gal, 10 – 15HP – 120 Gal)

Tri-Voltage, TEFC Motor

UL and UL-C Approved Control Panel

ONE STAGE: Air is compressed one time (“Single Stage”) but with 100% Duty Cycle

• Pressure is maintained 100% of the time.

• Ideal for automotive repair and body shops

• Reliable and efficient compressed air in a compact design

• Allow for 100% duty in a extremely quiet, user friendly package

ROTARY SCREW COMPRESSION • ONE STAGE

Electric – Rotary Screw Compressor

• 150 PSIG STANDARD (125 PSIG AVAILABLE 10-15 HP)

• CONTINUOUS OPERATING CAPABILITY

• SPACE SAVING DESIGN

• ACROSS-THE-LINE MOTOR STARTER

• ASME/CRN RECEIVER TANK

• TRI-VOLTAGE, TEFC MOTOR

• UL AND UL-C APPROVED CONTROL PANEL

• 100% FACTORY TESTED AT FULL PRESSURE

• 1 YEAR “BUMPER TO BUMPER” WARRANTY

(OPTIONAL UPGRADE TO 5 YEAR WARRANTY AVAILABLE)

• PRODUCT LINEUP INCLUDES: 8 MODELS

Manufacturer Info

Quality Testing and Performance

All units are assembled in the U.S.A. and are completely tested at full pressure before shipping. Test data is recorded and maintained for each and every unit.

Customer Satisfaction

Every unit has a data tag with the unit’s serial # and the BelAire® toll free support number. Any problem? Just call and they’ll take it from there!

The Best Warranty in the Industry

PARTS: The entire unit is covered including belts and valves.

LABOR: All field service and part delivery is covered.

Best Sellers

- Start-Stop Pressure Switch Control

- ASME Tank and Safety Valves

- Fully-Enclosed Belt Guard

- Tank Drain and Discharge Valve

- Solid Cast Iron Cylinders

- Overload Protection – No Magnetic Starter Required

- Power Cords (Portable Units) 115 Volt

- 100% Factory Tested

- Assembled in the U.S.A.

- 1 Year Manufacturer’s Warranty

- SPECIFICATIONS:

- HP: 2

- Voltage/Ph.: 115/230/1

- CFM@40psi: 8.3

- CFM@100psi: 7.1

- Tank: 26V

- Max Pressure: 135

- Ship Weight: 165 lbs.

- Size: 26Lx 26W x 51H

- Start-Stop Pressure Switch Control

- ASME Tank and Safety Valves

- Fully-Enclosed Belt Guard

- Tank Drain and Discharge Valve

- Cast Iron Cylinders

- Swedish Steel Valves

- Aluminum Heads and Coolers for Superior Cooling

- 100% Factory Tested

- Assembled in the U.S.A.

- 2 Year Manufacturer’s Warranty

- SPECIFICATIONS:

- HP: 5

- Voltage/Ph.: 230/1

- CFM@100psi: 15.3

- CFM@175psi: 13.7

- Tank: 60V

- Max Pressure: 165

- Ship Weight: 300 lbs.

- Size: 29L x 20W x 68H

- Start-Stop Pressure Switch Control

- ASME Tank and Safety Valves

- Fully-Enclosed Belt Guard

- Tank Drain and Discharge Valve

- Magnetic Starter

- Cast Iron Cylinders

- Swedish Steel Valves

- Aluminum Heads and Coolers for Superior Cooling

- 100% Factory Tested

- Assembled in the U.S.A.

- 2 Year Manufacturer’s Warranty

- SPECIFICATIONS:

- HP: 7.5

- Voltage/Ph.: 208-230/1

- CFM@100psi: 25.3

- CFM@175psi: 22.3

- Tank: 80V

- Max Pressure: 175

- Ship Weight: 479 lbs.

- Size: 39L x 24W x 77H

- 12 Volt Electric Start and Recoil Start

- 12 Alternator (Honda and Kohler Models)

- Start Key / Panel

- Oil Monitor

- Engine Slowdown (Pilot Valve)

- Fully Enclosed Belt Guard

- EZ Pull Tank Drain

- ASME Tank and Safety Valves

- 3/4” Tank Discharge Valve

- 100% Factory Tested

- Assembled in the U.S.A.

- 2 Year Manufacturer’s Warranty

- SPECIFICATIONS:

- HP: 13

- Engine: Honda

- Electric and Recoil Start: Standard

- CFM@100psi: 25.3

- Tank: 30H

- Max Pressure: 175

- Ship Weight: 378 lbs.

- Size: 45L x 19W x 45H

- Alternator

- Magnetic Motor Starters

- Start-Stop Dual Pressure Switch Control

- 1” Tank Discharge Valve

- Fully Enclosed Belt Guard

- ASME Tank and Safety Valves

- 100% Factory Tested

- Assembled in the U.S.A.

- 2 Year Manufacturer’s Warranty

- SPECIFICATIONS:

- 15 (2×7.5)

- Electrics V/ph.: 208-230/1

- CFM@100psi: 50.5

- Tank: 120H

- Max Pressure: 175

- Mag Starter: Included

- Ship Weight: 886 lbs.

- Size: 77L x 27W x 56H

7.5HP Belt Drive Rotary Screw Air Compressor with Dryer

Shop @ ToolTopia.com: #BELBR75501D

- Includes Dryer

- Low Sound Enclosure

- 150 psig Standard

- Continuous Operating Capability

- Space Saving Design, <12 ft2

- Across-The-Line Motor Starter

- ASME/CRN Receiver Tank

(5 – 7.5HP – 60 Gal, 10 – 15HP – 120 Gal) - Tri-Voltage, TEFC Motor

- UL and UL-C Approved Control Panel

- 100% Factory Tested

- Assembled in the U.S.A.

- 1 Year Manufacturer’s Warranty (optional upgrade to 5 Year Warranty available)

- SPECIFICATIONS:

- HP: 7.5

- aCFM@150psi: 21.2

- Max Pressure: 150

- Tank: 60H

- Sound Level (dBA): 64

- Ship Weight: 570 lbs.

- Size: 56L x 22W x 50H